Tablet compression machine tooling is an integral part of the compression machine which is required to compress the tablets. Upper punch, lower punch and a die, these three components are known as a tablet compression tool.

Various pairs of such tools are installed on the compression machine to compress the tablets as per requirement.

Importance of tooling

Without the tooling of a compression machine we are not able to compress the tablets.

Following tablet attributes are dependent on the compression machine tooling

- Tablet weight

- Tablet shape

- Dimensions

- Marking

Tooling standard

Two tooling standards in the world are available for compression machines, one is known as TSM and the other one is EU standards.

What Is TSM Standards?

TSM is Tableting specification manual and these standards of tooling are used in the USA.The TSM is available in the form of a written manual.

What Is The EU Standard?

EU standards are known as European standards and are used outside the America or USA.

Unlike TSM, the EU standards are not available in the form of any written manual.

TSM Vs EU Standards

There is a difference between these two standards which is given as below

| Specifications | TSM | EU |

| Inside head Angle for B type tooling | 37° | 30° |

| Punch head configuration | Angled | Domed |

| Overall Punch length | 133.35 mm | 133.60 mm |

- Inside head angle of the punch for B type tooling as per TSM is 37°.

- Inside head angle of the punch for B type tooling as per TSM is 30°.

- Punch head configuration as per TSM is angled whereas according to EU tooling standards it is domed shape.

- According to TSM tooling standards the overall punch length is shorter than EU standards.

Types Of The Compression Machine Tooling

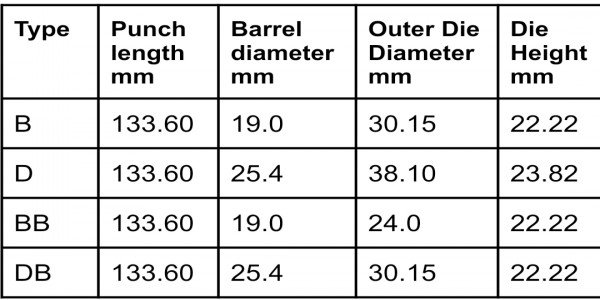

Following are the main types of compression machine tooling.

- B Type Tooling

- DType Tooling

- BB Tooling

- DB Tooling

| Type | Barrel dia.mm | Die Dia. mm | Die Height mm |

| B | 19.0 | 30.15 | 22.22 |

| D | 25.4 | 38.10 | 23.82 |

| BB | 19.0 | 24.0 | 22.22 |

| DB | 25.4 | 30.15 | 22.22 |

- Punch length in all types of the tooling remains the same which is 133.60 mm and the main difference lies between the diameter of the punch barrel and outer diameter of the die.

- Die height remains same in all the types of tooling except D type tooling where die height is 23.82 mm instead of 22.22 mm.

What Is The Difference Between B Type & D Type Tooling

The main differences between the B type tooling and D type tooling are as,

- The punch barrel diameter of the B type tooling is less as compared to the punch barrel diameter of the D type tooling.

- For B type tablet compression tooling outer die diameter is less than the outer die diameter of the D type tablet compression tooling.

- B type tooling has the capacity to exert less pressure and D type tooling has the capacity to exert large pressure.

- By using B type compression tooling we can compress small size tablets and by D type tooling we can compress the large size tablets.

| Tooling Type | Max Tab size (mm) Round/capsule |

| B | 16/19 |

| D | 25/25 |

| BB | 13/14 |

| DB | 19/19 |

Tooling Terminologies

Some common tooling Terminologies for punches and dies are given as,

For Punches

- Punch Head

- Head Flat

- Inside Head Angle

- Outside Head Angle

- Punch Neck

- Punch Barrel

- Punch Tip

- Cup Depth

- Overall Punch Length

- Punch Working Length

For Dies

- Die Height

- Die cavity

- Die Diameter

- Chamfer

- Die grooves

Punch Head

The main part of the punch which comes under the main pressure roller to apply pressure is known as punch head.

Punch Neck

The part of the punch below the punch head and before the punch barrel is known as punch neck.

Inside Head Angle

Inside head angle is inner portion of head part that play its role to pull the lower punches down when tablet is ejected out of the die cavity and pulls the upper punches out of the die when tablet is compressed inside the die cavity.

Common Tooling Shapes

Tablet tooling is available in different shapes depending upon the requirements.

The common shapes of tooling are round, oblong, capsule shape, star,half moon etc.

MOC Of Compression Tooling

The compression machine punches are made of Oil Hardened Non Shrinkable Steel (OHNS) and dies are made of High carbon high chromium stainless steel grade (HCHC).

Common Tooling Vendors

Following are some common tooling providers

- Natoli Engineering

- Thomas engineering

- Elizabeth Companies